Basic HTML Version

38

f. Use the roller control lever to start the

rollers and gather the bag.

12.

Unloading Speed:

Hydraulic power is used to drive the bag rollers

and wheels. Use the flow divider to set and

control the speed of the movement into the

bag. The system is designed so the bag rollers

and tires drive together. Move slowly to allow

the grain or material to be picked up evenly.

9.

Stopping:

a.

Stop the movement of the extractor.

• Depress the wheel drive pop valve to

stop the wheels.

• Place roller drive lever in neutral.

b. Run until the pick-up assembly is empty.

c. Run until the discharge auger is empty.

d. Slow engine RPM to low idle.

e. Place hydraulic circuit and PTO in neutral

and stop engine.

10.

Emergency Stopping:

Although all the augers should be emptied be-

fore shutting down, in an emergency situation

shut down all power and power units immedi-

ately. Correct the emergency before resuming

work.

11.

Restarting (Unit Full):

When the machine is shut down inadvertently

or for an emergency, the augers and pick-up

assembly will still be full of grain or material.

When restarting, the starting loads will be

higher than normal. When restarting, follow

this procedure:

a.

Start the tractor and place the hydraulic

lever in detent.

b. Use the tractor to back the extractor 1 foot

(60 cm) from the grain in the bag. This will

allow the grain to empty from the pick-up

assembly.

c. Set the engine RPM to low idle.

d. Engage the PTO to start the unloading au-

gers and empty the unloading system.

e. Increase engine speed to 3/4 throttle posi-

tion and completely empty the augers.

NOTE

Reverse gathering roller then move

tractor ahead a little to reduce the

amount of residual material being

gathered. Do not drive ahead very

much to minimize the chance of

tearing the plastic bag.

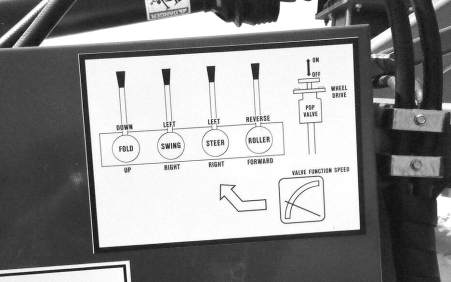

Fig. 37 CONTROL SCHEMATIC

NOTE

Slow the speed of forward motion to

reduce the load on the system.