SEO Version

22

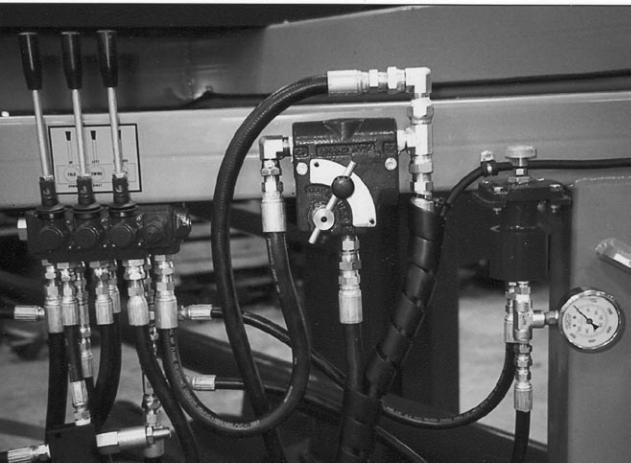

4.6 CONTROLS

Before starting to operate the

extractor to unload a bag, all

operators should fami l iarize

themselves with the location and

function of the controls.

1.

Raise/Lower:

This 3 position spring-loaded

to center-neutral lever con-

trols the fow of oil to the

frame cylinders. Pull on the

lever and hold to extend the

cylinders and raise the gath-

ering head. Push and hold

to retract the gathering head

into its working position.

Release the lever and it will

return to its center-neutral

position.

2.

Discharge Auger Swing:

This 3 position spring-loaded to center-neutral

lever controls the fow of oil to the discharge

auger swing hydraulic drive motor. Pull on the

center lever and hold to swing the auger to the

right. Push and hold to swing to the left. Release

the lever and it will return to its center-neutral

position.

3.

Right/Left:

This 3 position lever controls the fow of oil to

the motors on the wheels and gathering rolls.

Pull on the lever and place it into detent to power

the drives and move the Extractor into the bag.

Push and place into detent to reverse the drives

and back out of the bag. Move the lever to its

center position to stop the drives.

4.

Flow Control Valve:

This manually-set fow divider allows the opera-

tor to set the fow through the driving circuit from

0% to 100% by dumping the excess fow back

to the tractor. A scale on the face of the valve is

numbered from0 to 10 to defne the percent fow

from 0% to 100% fowing into the circuit. The

bag roller and wheel drive circuits are equipped

with a fow divider so the operator can adjust

the moving speed appropriate for the operat-

ing conditions. Loosen the lock and move the

pointer arm to the desired position. Tighten the

lock bolt. Adjust in small increments as a small

change can result in a large change to moving

speed.

Fig. 5 CONTROLS

5.

Relief Pressure:

This rotary valve sets the relief pressure in the

wheel drive circuit. The best performance is

obtained when the relief pressure is set for 700

to 1500 psi. Use the adjacent gauge to monitor

the system pressure.

6.

Pressure Gauge:

This gauge displays the pressure in the driving

circuit. Use in conjunction with the relief setting

valve to set the system pressure.

7.

Hydraulic Controls:

Use only the tractor hydraulic circuits that are

designed with a detent. Place the lever in detent

to provide a steady fow of oil to the circuits.

NOTE

When hooking the machine to the trac-

tor, place the circuit in detent. Pull on

the Raise/Lower control lever. It should

lower the gathering head frame to the

ground for correct machine operation. If

it does not, place control in neutral and

reverse hose hook-up or move the lever

to the other side to reverse the direction

of oil fow.

Powered by FlippingBook Publisher